What is the press brake dies?

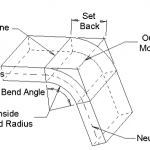

Press brake dies is a tool used by the press brake to form a sheet metal. This tooling consists of various parts, and the different tooling are made up of different parts.

lt mainly realizes the processing of the shape of the parts by changing the physical state of the formed material. it's a tool for making a blank into a part of a particular shape and size under the pressing of the press brake machine.

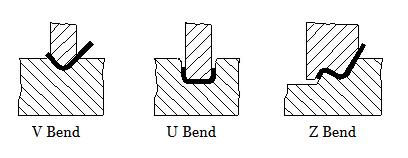

Commonly Used Press Brake Dies

Generally, the height of flanged edge L≥3t (t=plate thickness). If the height of the flanged edge is too small, even use bending die is not conducive to forming.

The Classification of Press Brake Dies

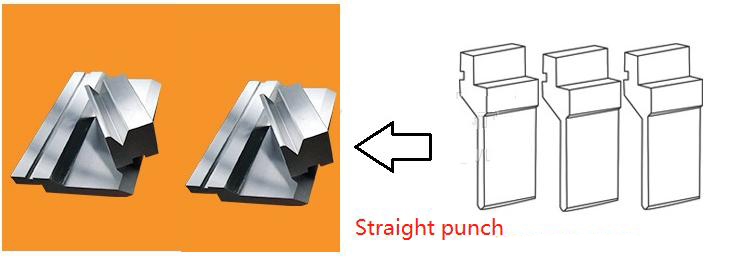

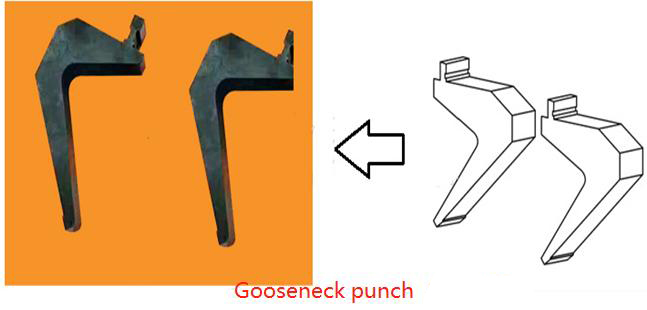

| Punch type | Main application |

| Straight punch | Fabricated angles ≥90° |

| Goose neck punch | Fabricated angles ≥90° |

| Acute punch | Fabricated angles≥30° |

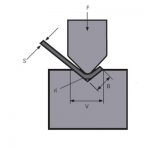

Die

| Punch type | Main Application |

| Sing V die | 1.While v angle = 88(ref), able to bend angles ≥ 90° |

| Double V die | 2. While V angle = 30°(ref), able to bend angles ≥ 30° |

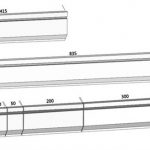

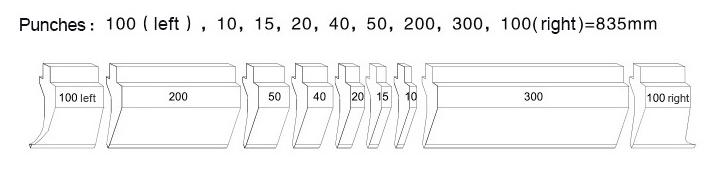

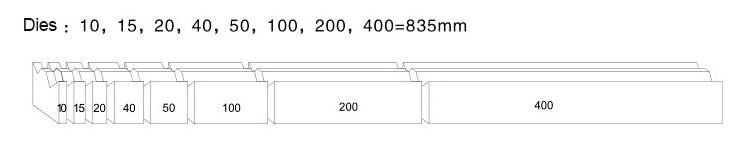

Press brake segment die

Generally, the standard length of the press brake punch and die set is 835mm. In order to bend workpiece in different length, the punch and die are separated into below size:

10+15+20+40+50+100+100+200+300=835

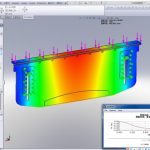

Press Brake Dies Materials

Generally, the materials of press brake die including T8 steel, T10 steel, 42CrMo, and Cr12MoV.Cr12MoV is also good material. The using performance can be satisfied, the process

performance is also good, but the price will be high.

42CrMo is a high strength alloy quenched and tempered steel with high strength and strong toughness. It can work under the temperature of -500°℃.

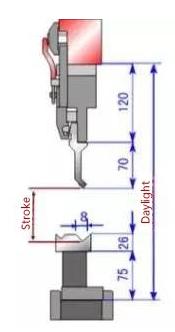

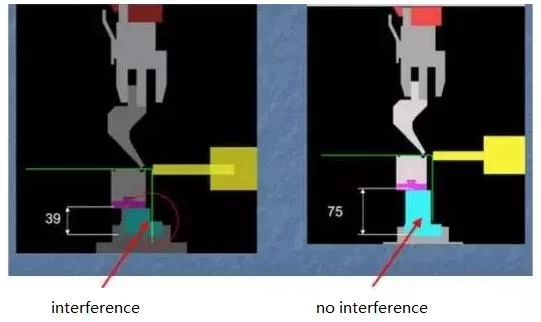

How to choose press brake parameters Press brake die height formula

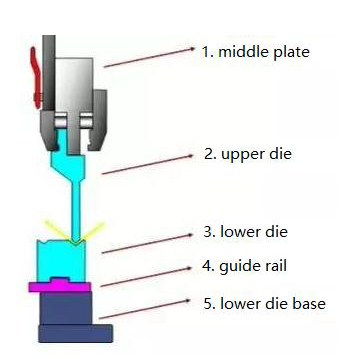

- Stroke (mm)=daylight - middle plate height - upper die height - lower die height (lower die height - 0.5V+t)

t = plate thickness ( mm )

Given: daylight 370mm, max stroke 100mm

Reach: stroke = 370-120-70-75-(26-0.5*8+t)= (83-t)mm

Note: 0.5V < max stroke

Please note the lower die base also have many different heights, which is used for different fabrication purpose. So don't forget this when choosing lower die base.

Lower die type

Generally, the lower die has a single V type and double V type, among which it is separated intothe separated die and full-length die. The different die is applied to a different fabricating pupose

However, the single-V die has a much wider application than double-V die, while the separateddie is more widely used than full-length die.

Lower die v width, V groove angle

V groove choosing & plate thickness (T):

| T | 0.5~2.6 | 3~8 | 9~10 | ≥12 |

| V | 6×T | 8×T | 10×T | 12×T |

The V angle of the lower die is the same as upper die's angle.

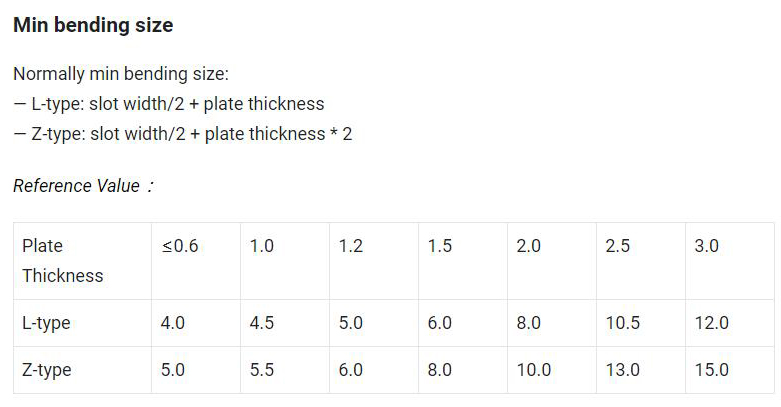

| Plate thickness | ≤0.6 | 1.0 | 1.2 | 1.5 | 2.0 | 2.5 | 3.0 |

| Die width | 4 | 6 | 8 | 10 | 12 | 16 | 18 |

In order to choose small v die for bending purpose in some special case, the spread of every punch should increase 0.2mm

For more detail please contact us ,we will provide you a full solution.