termékleírás

| Machine Model | GF3015 | |

| Cutting Area(length x width) | 3000mm×1500mm | |

| Laser Model | Fiber laser IPG-500W/1000W | |

| Laser Wavelength | 1,070-1,080nm | |

| CS Cutting Thickness | Max. 5mm/10mm | |

| SS Cutting Thickness | Max. 3mm/5mm | |

| Interface | USB,RJ45 | |

| X-Axis | Moving Speed | 50m/min |

| Stroke | 3000mm | |

| Position Accuracy | ±0.05mm/m | |

| Repeatability Accuracy | 0.05mm | |

| Y-Axis | Moving Speed | 50m/min |

| Stroke | 1500mm | |

| Position Accuracy | ±0.05mm/m | |

| Repeatability Accuracy | 0.05mm | |

| Z-Axis | Stroke | 50mm |

| Power Supply Requirement | 400V/50Hz/30A(36A) | |

| Continuous Working Time | 24 óra | |

| Machine Weight | Approximate 3000kg | |

| Dimension(length×width×height) | 4500mm×2300mm×1500mm | |

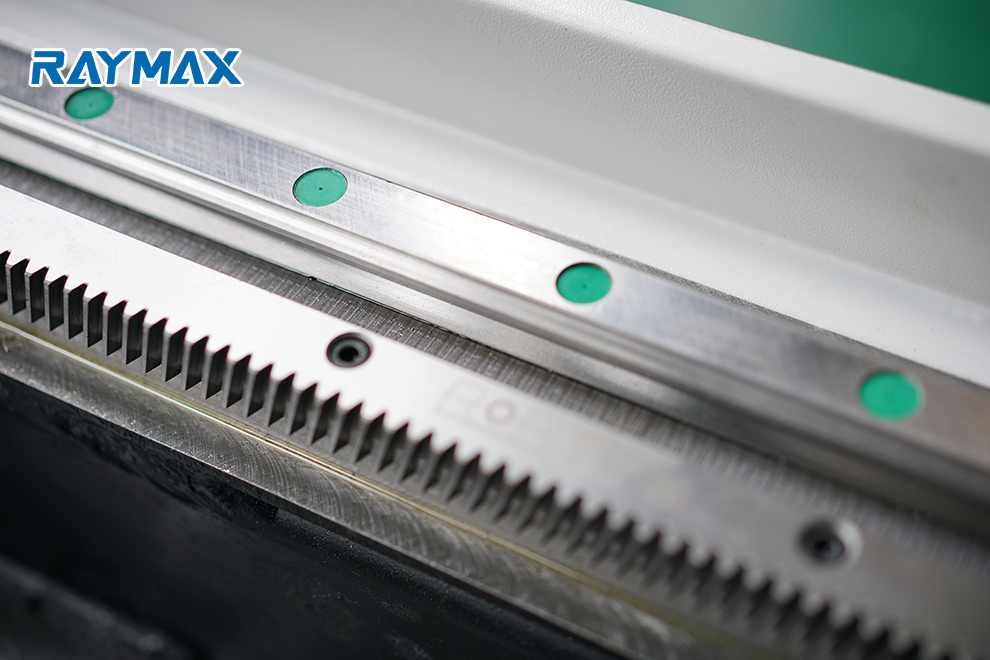

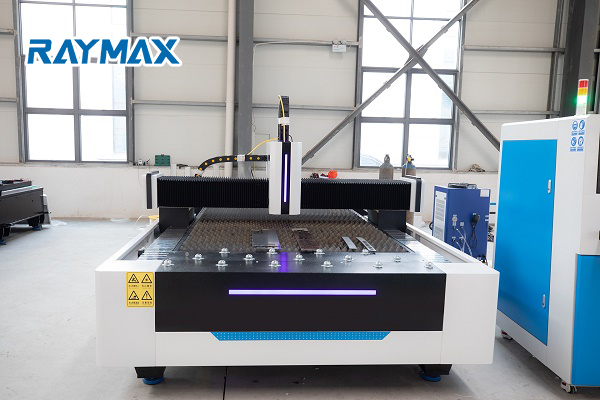

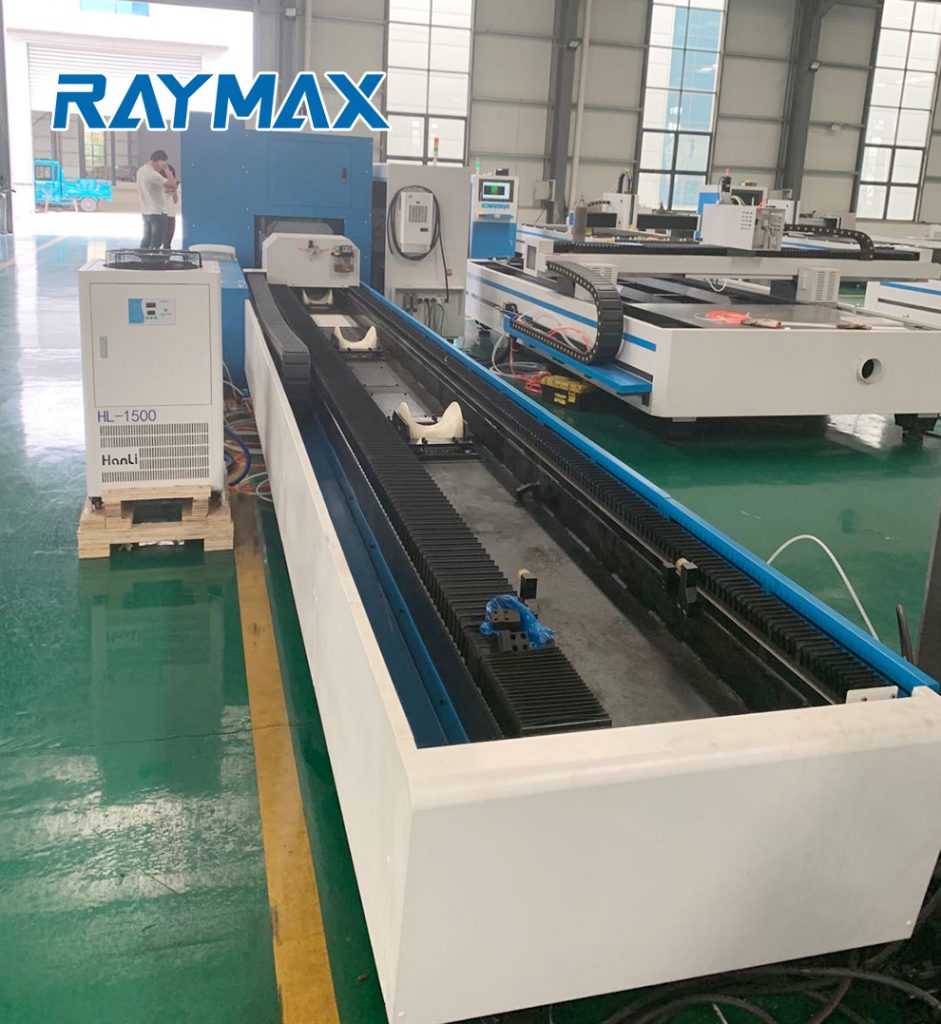

3015 CNC laser cutting machine adopts gantry-motion structure, linear guide, screw drive, AC servo motor and drives, and vacuum system (both sides), etc. The one-time processing area is 3m*1.5m.Not only that the equipment's design is advanced and reliable, but also that all key components are from both national and international well-known brands. In particular, we use Germany BECKHOFF' company's professional laser CNC system for the electrical control system.

This special laser CNC system has advantages of high integration, better control precision and more stable operation, therefore, in addition to the meet the requirement of cutting carbon steel plate, it can also meet the requirement of cutting SS plate, aluminum alloy, copper alloy and other materials.

Features:

1. Users-friendly operating interface

2. USB port and broadband interfaces

3. AC servo motor and drive;

4. Fast-response surface following;

5. Easy operated cutting retract function;

6. Straight line/circular arc interpolation fitting and kerf compensation functions;

7. Programming software Farley CNCKAD with automatic nesting functions;

8. Water chillers ensure machine's precise and stable running

9. CAD/CAM software package with powerful nesting function and edge-shared cutting function;

10. Ventilation dust removal device protect working environment from cutting emissions and metallic vapor;

11. Slag discharging device to facilitate slag discharging.